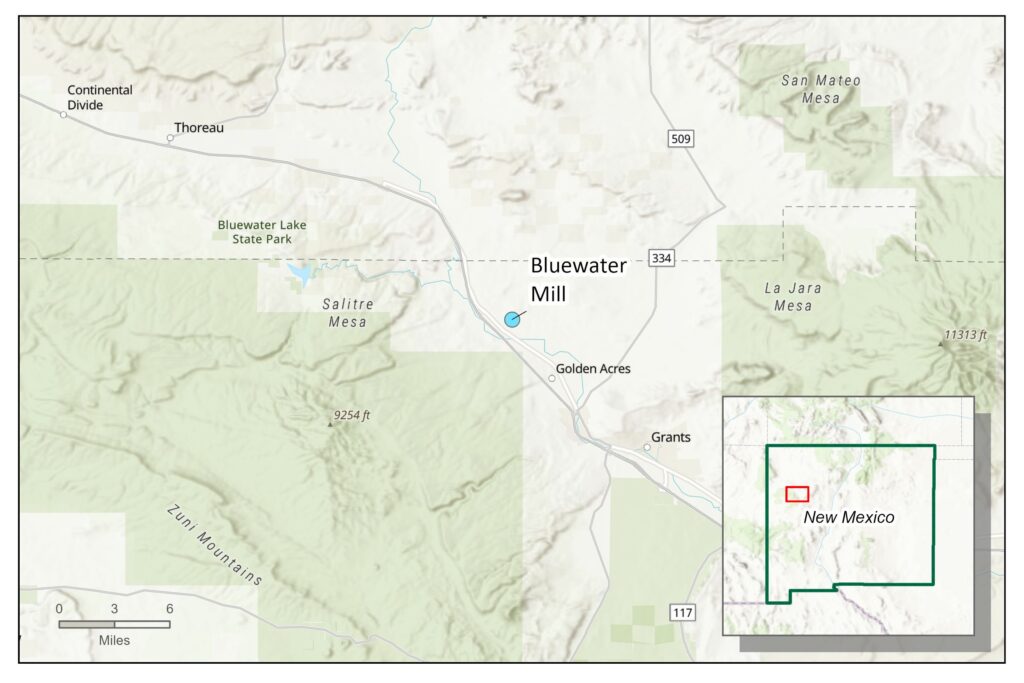

Location

The Bluewater mill site (also referred to as the Bluewater disposal site) is located in Cibola County, roughly 9 miles northwest of Grants, New Mexico, and roughly 6 miles northwest of Milan, New Mexico.

Ownership and History

The Bluewater mill was originally constructed by the Anaconda Copper Company as a carbonate-leach mill in 1953 to process uranium ore that was mined nearby. In 1957, an acid-leach mill was constructed to process sandstone uranium ore from the Jackpile-Paguate mine, north of Laguna Pueblo. The carbonate-leach mill closed, and the acid-leach mill reduced production due to economic conditions in 1959, but the acid-leach mill resumed full operations again in 1967. As of 1978, the acid-leach mill’s capacity increased to 6,000 tons of ore per day. In 1977, the Anaconda Copper Company became a subsidiary of the Atlantic Richfield Company (ARCO). The U.S. Department of Energy Office of Legacy Management (DOE-LM) currently manages the site under Title II of the Uranium Mill Tailings Radiation Control Act of 1978 (UMTRCA). Title II of UMTRCA authorized the regulation of commercial uranium mills operating on or after 1978.

Reclamation and Regulatory Jurisdiction

The Bluewater mill is under the jurisdiction of Title II of UMTRCA, which applies to uranium mill sites which were under active U.S. Nuclear Regulatory Commission (NRC) licenses when UMTRCA was enacted. Title II of UMTRCA stipulates that after reclamation is complete, the federal government or the host state is responsible for the long-term custody of the site. The DOE-LM assumed responsibility for the Bluewater site.

ARCO began decommissioning the mill in 1989 and began reclamation in 1991. All mill tailings, contaminated soils, demolished mill structures, and any additional contaminated materials were encapsulated in onsite disposal areas by 1995. The main unlined tailings disposal cell covers approximately 354 acres and contains an estimated 23 million tons of tailings and other contaminated materials. The carbonate tailings disposal cell covers approximately 54 acres and contains an estimated 1.3 million tons of contaminated materials. The carbonate disposal cell contains carbonate mill process tailings. Acid mill process tailings are in the main disposal cell. Neither cell had a liner. After some time, groundwater at the site showed elevated concentrations in constituents as a result of tailings liquid seeping into the alluvial and bedrock units below the ground surface. In an attempt to reduce the impact, Anaconda Copper Company drilled an injection well into the Yeso formation and pumped the fluids from the main tailings impoundment between January 1960 and December 1965. Contaminated water moved upward into the San Andres Glorieta (SAG) aquifer from the Yeso formation below. The SAG is the main groundwater source for the region and supplied the process water needed for mill operations. In 1990, ARCO applied to the NRC for alternate concentration limits (ACLs). ACLs are alternative compliance values adopted when established maximum concentration limits are unable to be met, providing that the proposed ACL does not pose a present or potential future hazard to human health or the environment.

The NRC approved ARCO’s ACL in 1996 and the New Mexico Environment Department (NMED) subsequently terminated its permits on the site. The site was transferred to DOE-LM for long-term care and maintenance in 1997. A Long-Term Surveillance Plan (LTSP) dictates the actions of DOE-LM.

As part of the compliance strategy, the groundwater monitoring network consists of 19 wells located inside the Bluewater site boundary where samples of the main constituents of concern are analyzed semiannually. In addition to the main tailings disposal cell and the carbonate tailings disposal cell, there are three other engineered disposal structures adjacent to the carbonate tailings disposal cell to contain contaminated material from milling activities.

Title II of UMTRCA also stipulates that the site licensee (ARCO in this case) is responsible for remedial action. ARCO encapsulated the tailings in two disposal cells and other contaminated materials in disposal areas meeting NRC design requirements. NRC’s cleanup and reclamation standards are codified in Title 10 Code of Federal Regulations (CFR) Part 40, Appendix A. The standards comply with NRC-approved ACLs. NRC issued the site the general license for UMTRCA Title II sites (10 CFR 40.28) and transferred it from ARCO to DOE-LM for long-term custody in 1997. ARCO is not considered a responsible party at this site.

Timeline for Completion of Cleanup Activities

DOE-LM manages the disposal site according to a site-specific LTSP to ensure the disposal cells continue to protect against contaminants releasing into the environment (DOE-LM is currently updating this plan to reflect current site conditions). DOE-LM conducts annual inspections of the site to evaluate the conditions of surface features, performs site maintenance, and monitors groundwater to ensure contaminated groundwater is not released in concentrations greater than those approved in the ACL agreement and stated in the LTSP. The reclamation for the site is complete. In accordance with 40 CFR 192.32, the disposal cells are designed to be effective for 1,000 years, to the extent reasonably achievable, and for at least 200 years in any case. The general license has no expiration date, and DOE-LM’s responsibility for the site will last indefinitely.

Coordination Between State and Federal Agencies

NMED works with DOE-LM on site monitoring and repair activities.

Anticipated Funding Requirements

The DOE-LM is the responsible party for the site, and is therefore, responsible for funding remediation and cleanup activities.

Disclaimer

Site reviews in this report provide the reader with a general history and status of permitted mines and mills. For brevity, they may not provide all relevant details or agency actions related to each site.