Thermo Eberline Facility

Company Name / Public Involvement: Thermo Eberline LLC

License Number: SO067

Date Posted: 7/24/2025

Location: 5981 Airport Road

Santa Fe, NM 87507

Full Thermo Eberline LLC Decommissioning Plan

- Decommissioning Plan Overview & Summary

- Dated 05/28/2025 Submittal Letter Final Decommissioning Plan (PDF)

- Purpose & Scope, Facility Operating History, & Description

- Radiological Status of Facility, Dose Modeling, ALARA Analysis, and Planned Decommissioning Activities

- PM & Organization, Health & Safety During Decomm, Environmental Monitoring & Control

- Radioactive Waste Management, Quality Assurance, & Facility Radiation Surveys

- Financial Assurance

- *Glossary of Acronyms & Abbreviations

- *Supporting Documentation & Attachments

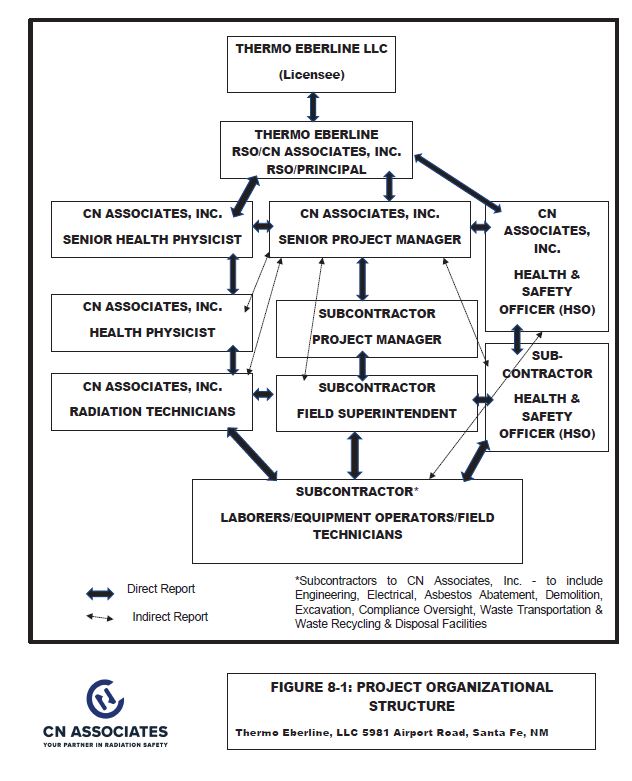

8.0 Project Management & Organization

The following is a detailed description of the Project Management and Organization of the decommissioning plan as documented in the Thermo Eberline LLC Final Decommissioning Plan.

8.1 Decommissioning Management Organization

The Licensee’s decommissioning management team will be led by CN. CN will serve as the prime contractor reporting to the Licensee’s management team and NMED. CN will provide radiation assessment, characterization, remedial and compliance survey support for the project and will be supported by contractors specializing in asbestos abatement, asbestos abatement compliance oversight, building and structure dismantlement and demolition, demolition compliance monitoring, subsurface soil excavation using augers, removal and waste transportation, recycling and disposal, as needed.

All work activities at the site involving licensed radioactive materials shall be performed in accordance with established plans and procedures established for site decommissioning tasks in accordance with the site radiological license (License No. SO067-36), this DP and CN procedures for radiological work. Additional plans will be developed to facilitate general work activities that do not involve the management of licensed radioactive materials. The CN executive project management team is responsible for implementing the approved decommissioning activity plans and procedures in accordance with the applicable laws and regulations governing the decommissioning process at the site. The CN team is also responsible for retaining and allocating the appropriate resources necessary to accomplish the approved decommissioning tasks, providing the requisite radiation awareness training where applicable, and assuring work is performed in accordance with industry standards.

The CN onsite management team is responsible for the day-to-day oversight of the field operations associated with the approved decommissioning tasks outlined in this DP and is responsible in overseeing the decommissioning work performed by any contractors at the site. The CN onsite management team is responsible for ensuring that all work performed is appropriately authorized and follows established programs and procedures. All members of the project team and contractors have the individual and joint responsibility and authority to stop work on any activity that they deem hazardous or unsafe on the job site. The project organizational structure is displayed in an organizational chart in Figure 8-1 and detailed below.

- Thermo Eberline LLC– Radiation Safety Officer (RSO)- has the overall responsibility for management of Licensee’s radioactive materials license, directing the contractor organization to accomplish approved decommissioning tasks, and the safe conduct of the project in compliance with the applicable laws, regulations, and permit requirements. This role has been contracted to CN. The RSO provides the senior project management oversight for implementation and execution of the project decommissioning plan including scheduling, funding, overall task management and regulatory interface.

- CN Principal– has final authority in approving the site decommissioning activities, contracts, programs, and procedures, and ensuring that the project team is supplied with the training, equipment, and materials necessary for a safe work environment.

- CN Radiation Safety Officer (CN RSO)- has the specific responsibility and authority to implement and manage CN’s Radiation Protection Program (RPP) during decommissioning including the overall content of the RPP during decommissioning. The CN RSO is also responsible for directing the radiation technician staff, as well as providing direction and guidance on the development, maintenance, oversight and implementation of radiation protection programs and procedures specific to the decommissioning project. If the CN RSO, or duly authorized representative, believes an operation to be unsafe, he or she has the responsibility and authority to halt that operation until the operation has been deemed safe.

- CN Health Physicists (HPs)- have the responsibility for providing technical direction for radiological surveys and sampling activities. HPs develop technical support documents and conduct data validation of survey and sampling results and develop radiation protection procedures for conducting decommissioning activities.

- CN Radiation Technicians (RTs)- have the responsibility for conducting radiological surveys and sampling activities in accordance with approved procedures. Additionally, RTs provide radiation protection surveillance activities (job coverage) in support of decommissioning activities for the protection of workers and in support of decommissioning plans and procedures.

- CN Project Manager (CNPM)– is responsible for coordinating CN and subcontractor resources at the site, coordinating daily work briefings and debriefs, ensuring employee awareness of programs for compliance with CN’s RPP and Site Health And Safety Plan (HASP), coordinating CN and subcontractor resources, identifying and coordinating solutions to the safe and effective completion of site work, project scheduling, coordination for technical and management review of project documentation, and monitoring project progress, schedule and budget.

- CN Health & Safety Oversight (HSO)– is responsible for the execution of the site HASP and safety leadership and performance on the job site, as well as for all health and safety activities during the implementation of work activities on a day-to-day basis. The HSO is responsible for coordination with site contractors to ensure the implementation of onsite safety regulatory and health requirements including appropriate implementation of radiological health and safety in coordination with the CN RSO, CN Health Physicists and CN Radiation Technicians, and compliance with plans and procedures. The HSO has the responsibility and authority to immediately stop any work activity that is judged unsafe or that might result in a violation of the applicable laws and regulations governing the decommissioning activities at the site.

- Subcontractor Project Manager (SPM)- is the lead individual for each subcontractor’s organization responsible for the safe implementation of all assigned subcontractor tasks in accordance with the executed contracts and project plans, subcontractor’s HASP, ensuring compliance of subcontractor personnel with CN’s HASP, communicating any changes in circumstances that have the potential to affect the completion of the decommissioning tasks as approved. The SPM is also responsible for allocating the appropriate resources necessary to accomplish contracted decommissioning tasks, providing the requisite training for subcontractor personnel, and assuring the quality of work performed under his/her direction is in compliance with contractual obligations, site work plans and general industry standards applicable to the subcontractor’s area of expertise.

- Subcontractor Field Superintendent (CFS)- is responsible for all operational aspects of decommissioning project performance, including the day-to-day performance of the field operations associated with the decommissioning tasks specified in the subcontractor’s contract and applicable work plans. He/She has the responsibility and authority to immediately stop any work activity that is judged unsafe or that might result in a violation of the applicable laws and regulations governing the decommissioning activities at the site.

- Subcontractor Health & Safety Officer (SHSO)- is responsible for the oversight of the planned and scheduled decommissioning activities that are the responsibility of the subcontractor and for ensuring subcontractor staff are working in compliance with the subcontractor’s HASP, coordinating with the CN HSO and the CNPM/HP as necessary for compliance with RPP. The SHSO consults with subcontractor field, technical and management personnel to ensure that the decommissioning project’s programs, plans, and procedures are appropriately and safely implemented in the field. He/She has the responsibility and authority to immediately stop any work activity that is judged unsafe or that might result in a violation of the applicable laws and regulations governing the decommissioning activities at the site.

- Laborers / Equipment Operators – Subcontractor personnel have the responsibility and authority to have reviewed and understand the CN HASP, follow their project specific HASP, and complete site radiation awareness training prior to commencement of work. Subcontractor personnel have the authority and responsibility to stop work on any activity that they deem hazardous or unsafe on the job site. It is the responsibility of all personnel to report to work in condition to work, and to wear appropriate personal protective equipment. Personnel are expected to understand their work assignment and to be sure that they are qualified to perform the assignment. If workers do not understand their assignments or feel that they are not qualified or trained, they are required to notify their supervisor.

8.2 Decommissioning Task Management

The management of decommissioning tasks involving licensed radioactive materials will be accomplished by CN having primary responsibility for execution and oversight of subcontractors. Plans for specific decommissioning tasks involving non-radiological work elements may be developed based on the scope of the tasks as outlined in work plans developed by CN for the Licensee and in coordination with subcontractors in support of contracted work elements.

CN staff and subcontractors will be briefed on the overall work elements and objectives, how work elements between CN and subcontractors will be integrated into the overall plan, sequenced and managed by CN and the subcontractor’s management and staff. The management of tasks to be completed under the three phases of site decommissioning falls into the following four groups:

- Pre-Demolition Site Preparations, including:

- Permitting for building demolition.

- Development of project execution plans that stipulate the means, methods, procedures, roles, and responsibilities of project team entities in execution of site decommissioning work.

- Pre-demolition inspection of the building for confirmation of removal of universal (fluorescent bulbs, mercury switches, etc.) and special wastes (non-radioactive).

- Securing radioactively impacted subsurface soil areas to ensure containment and prevent comingling of non-rad wastes with impacted soil.

- Baseline air monitoring for particulates and background radioactivity.

- Confirmation of termination of site utilities and establishment of temporary utilities.

- Establish waste staging areas, methods of staging building demolition wastes and protocols for waste inspection and radiological screening.

- Asbestos abatement of the roof, monitoring, clearance, packaging, and disposition of asbestos wastes.

- Holding project startup meetings with subcontractors to review the project tasks, sequencing, roles and responsibilities, and task integration and decision-making necessary to support overall task execution. Review of CN HASP, discussion, Quality and

- Assurance and Radiation Awareness Training.

- Building Demolition/Land Surface Materials Removal

- Confirm the means, methods, sequence and schedule for building dismantlement, demolition, and waste staging in accordance with the project plan and project team.

- Complete baseline radiation clearance surveys of subcontractors and equipment upon arrival at the site. Provide workers Radiation Awareness Training.

- Identify the primary CN and subcontractor on site managers and points of contact for work coordination.

- Conduct daily Plan of the Day (POD) briefings with subcontractors to review daily tasks to be conducted, hazards, safety review, monitoring plans, results, assess engineering control effectiveness, and establish sequence of work elements and applicable modifications. Discuss safety observations and/or concerns and measures to enhance worker safety, awareness, and communication.

- CN to conduct oversight of subcontractor work, inspection of site engineering controls (barriers and access controls to radiologically impacted subsurface soil), dust mitigation controls, storm water pollution prevention plan controls (SWPPP), spill prevention control and countermeasures (SPCC), periodic radiation monitoring of workers, equipment, air and demolition waste containment and monitoring.

- Subcontractors will be retained by CN for building dismantlement and demolition, dust monitoring and off-site transportation and recycling or disposal of wastes. Subcontractors will maintain primary responsibility for the management of subcontractor staff with subcontractor management reporting to CN.

- Soil Removal & LLRW Management

- Establish the means, methods and sequence of soil removal and waste staging and in accordance with the project soil removal plan.

- Establish radiation protection program for soil removal including design and construction of containment, air monitoring protocols, contamination controls and PPE.

- Provide workers Radiation Awareness Training.

- Identify the primary CN and subcontractor on site managers and points of contact for work coordination.

- Conduct daily POD briefings with subcontractors to review daily tasks to be conducted, hazards, safety review, monitoring plans, results, assess engineering control effectiveness, and establish sequence of work elements and applicable modifications. Discuss safety observations and/or concerns and measures to enhance worker safety, awareness, and communication.

- CN to conduct oversight of subcontractor work, inspection of site engineering controls (barriers and access controls to radiologically impacted subsurface soil), dust mitigation controls, SWPPP and SPCC controls, periodic radiation monitoring of workers, equipment, air and demolition waste containment and monitoring.

- Subcontractors will be retained by CN for soil removal, installation of engineering controls for deep soil excavation, installation of containment, backfilling, dust monitoring and off-site transportation and recycling or disposal of wastes.

- Post-Removal Surveys, Testing & FSS

- Establish survey plans, instrumentation, Data Quality Objectives (DQOs), MDAs for ROCs, survey grids and sampling locations and analytical methods.

- Employ CN SOPs for data recording, survey review, data QA/QC, and sequence of data review to establish compliance with DOQs.

- Provide workers Radiation Awareness Training for subcontractors.

- Identify the primary CN and subcontractor on site managers and points of contact for work coordination.

- Conduct daily POD briefings with subcontractors to review daily tasks to be conducted, hazards, safety review, monitoring plans, results, assess engineering control effectiveness, and establish sequence of work elements and applicable modifications. Discuss safety observations and/or concerns and measures to enhance worker safety, awareness, and communication.

- CN to conduct oversight of subcontractor work, inspection of site engineering controls (barriers and access controls to radiologically impacted subsurface soil), dust mitigation controls, SWPPP and SPCC controls, periodic radiation monitoring of workers, equipment, air and demolition waste containment and monitoring.

- Subcontractors will be retained by CN for monitoring well installation and abandonment and off-site transportation and recycling or disposal of investigation derived wastes (IDW). Subcontractors will maintain primary responsibility for the management of subcontractor staff with subcontractor management reporting to CN.

Decommissioning tasks are evaluated for radiological purposes in accordance with CN’s Radiation Safety Manual. The Radiation Safety Manual requires work activities in restricted areas to be conducted under a Radiation Work Permit (RWP). RWPs are developed in accordance with procedure CN-RP-002 Radiation Work Permits.

Decommissioning of the building and contents under Phase 1, foundations and concrete and asphalt under Phase 2 will involve dismantlement and demolition of radiologically non-impacted structures and contents. Foundation and soil removal under Phase 3 will involve the construction of containment, establishment of contamination controls (contaminant reduction and exclusion zones, monitoring and decontamination), management of LLRW including containment and transport for off-site disposal, surveys, sampling and laboratory testing during and post-removal, backfilling and site restoration and groundwater testing following soil removal.

Radiation monitoring of workers, soil, wastes and air will be conducted by CN to provide confirmation of non-impacted materials and to support segregation of impacted from non-impacted materials. RWPs will be issued in support of radiological controls for the removal and management of contaminated materials.

CN-RP-002 Radiation Work Permits provide detailed instructions for developing specific radiological controls and requirements for each task. The radiological controls may include, but are not limited to, requirements for protective clothing, dosimetry, respiratory protection, radiological surveys, personnel monitoring, and Stop-Work criteria.

RWPs are developed by health physics personnel knowledgeable of task requirements and the radiological conditions of the work area. Radiation Protection Management personnel approve the RWP after a review of the task requirements and radiological conditions. RP management personnel provide oversight of radiological and review radiological surveys on an ongoing basis. If the work task requirements change, or the radiological conditions change, a stop work is issued and the RWPs are revised as needed to ensure the controls are appropriate for the new conditions.

At the completion of tasks RWPs are terminated and filed with other decommissioning records. Before individuals perform decommissioning tasks controlled by RWPs, they must sign an RWP Worker Acknowledgment Form that documents that they have read, understood and will comply with the requirements of the RWP. The RWP procedure contains a Job Briefing Attendance Sheet that is used to document ongoing job briefings as needed during the completion of the work.

8.3 Decommissioning Management Positions and Qualifications

Licensee Radiation Safety Officer (RSO):

The Licensee’s RSO has the overall responsibility for directing the contractor organization to accomplish approved decommissioning tasks as mandated by the Licensee’s radioactive materials license, and the safe conduct of the project in compliance with the applicable laws, regulations, and permit requirements. This individual provides the senior project management oversight for implementation and execution of the project decommissioning plan including scheduling, funding, and overall task management.

Ron Cardarelli, CN Principal, is contracted as the Licensee’s RSO. Mr. Cardarelli holds a MS in Radiation Science from Georgetown Medical School, a BS in Environmental Health/Public Health from UMass Amherst and has over 40 years of work experience including the NRC, nuclear power plant decommissioning, commercial site decommissioning and radiation consulting services.

CN Radiation Safety Officer (RSO):

The RSO has the specific responsibility and authority to implement and manage the Radiation Protection Program (RPP) during decommissioning including the overall content of the RPP during decommissioning. The RSO is also responsible for directing the radiological staff, as well as providing direction and guidance on the development, maintenance, oversight and implementation of radiation protection programs and procedures specific to the decommissioning project. The RSO provides direction and guidance on, and is responsible for the development, maintenance, oversight and implementation of radiation protection programs and procedures specific to the site or project. As part of this responsibility, the RSO, or duly authorized representative, will review the radiation safety program annually and document the review. The RSO will ensure that the plans, processes, and procedures implemented on the project are consistent with the commitment to the ALARA philosophy and stated ALARA goals.

Mr. Ron Cardarelli serves as the CN RSO.

CN Radiation Protection Manager (RPM):

The Site radiological Protection Manager (RPM) will have primary responsibility for radiation protection during on-site activities and will also serve as the primary point of contact during normal day-to-day operations at the Site on radiological issues. The RPM will also be responsible for ensuring that site activities are performed in accordance with applicable radiological regulations, the site radiological license, as well as established programs and procedures. The RPM will be capable of directing the day-to-day surveillance activities of the HP Technicians.

The CN RPM holds a degree in science or engineering or has equivalent knowledge and will have a minimum 10 years of experience in radiation protection, at least five years of which will be in a project management role.

CN Project Manager (CNPM):

The CN Project Manager is the technical lead responsible for implementing the approved decommissioning activity plans and procedures in accordance with the applicable laws and regulations governing the site. The CNPM supports the selection of subcontractors and for their oversight to ensure that all work activities are accomplished in a safe manner. The CNPM is responsible for communicating any changes in circumstances that have the potential to affect the completion of the decommissioning tasks on schedule. The CNPM is also responsible for allocating the appropriate contractor resources necessary to accomplish the approved decommissioning tasks, providing the requisite training, and assuring the quality of work performed under his direction.

The CNPM will hold a degree in a science or engineering field (or have equivalent knowledge) and will have a minimum five years of experience in environmental site remediation, at least five years of which will be in a supervisory or management role. Mr. John McTigue serves as the CNPM and holds BA and MA degrees in science and has more than 35 years of experience in environmental site remediation including over 20 years in the decommissioning of licensed radioactive facilities.

Site Health & Safety Officer (HSO):

The Site Safety & Health Officer (HSO) is responsible for the day-to-day implementation and oversight of onsite safety and health requirements including appropriate implementation of both radiological and non- radiological health and safety, including regulatory compliance. The HSO will coordinate safety issues related to the site with all team members including the RSO and RPM, and contractor personnel. The HSO will also keep the RPM/RSO informed of issues related to the radiological status of the site and activities performed at the site. The HSO will consult with and advise the project Field Superintendent regarding the safe conduct of work activities at the site and will perform routine safety inspections to ensure compliance with applicable regulatory requirements. The HSO has the responsibility and authority to immediately stop any work activity that is judged unsafe or that might result in a violation of the applicable laws and regulations governing the decommissioning activities at the site. The HSO will have the ability to recognize potential physical, radiation, and chemical safety problem areas in operations and to advise workers and responsible line management personnel regarding appropriate and compliant control measures.

The requisite qualifications for the project HSO are a minimum five years of experience in areas such as construction safety, environmental worksite worker safety, radiation safety, radiation monitoring, emergency preparedness, industrial safety, and personnel exposure monitoring and evaluation.

Subcontractor Project Manager (SPM):

The subcontractor’s project manager (SPM) is responsible for the implementation of all assigned tasks in a safe manner, communicating any changes in circumstances that have the potential to affect the completion of the decommissioning tasks as approved. The SPM is also responsible for allocating the appropriate resources necessary to accomplish the approved decommissioning tasks, providing the requisite training, and assuring the quality of work performed under his/her direction. The SPM will also direct the activities of the Field Superintendent.

The SPM will hold a degree in a science or engineering field (or have equivalent knowledge) and will have a minimum five year of experience in environmental site remediation, at least five years of which will be in a supervisory or management role.

Subcontractor Field Superintendent (SFS):

The Subcontractor Field Superintendent is responsible for operational aspects of decommissioning tasks that the subcontractor has been retained to fulfill including the day-to-day performance of the field operations associated with the approved decommissioning tasks outlined in this DP. The field superintendent consults with the CPM and HSO to ensure that the subcontractors work activities are safely implemented in compliance with project objectives and applicable plans the field. This individual is responsible to ensure that all work performed is appropriately authorized and follows the approved procedures, plans, policies, and permits governing such work. The SFS, as all site employees, has the responsibility and authority to immediately stop any work activity that is judged unsafe or that might result in a violation of the applicable laws and regulations governing activities at the site. The SFS also provides direct supervisory oversight of the technician, laborer, and subcontracted services workforce and is responsible to verify that workers satisfy the requisite training requirements, and to appropriately document the work activities and site safety briefings performed in support of the decommissioning tasks.

The SFS will have a minimum five years of experience in the role the subcontractor has been engaged to fulfill.

8.4 Radiation Safety Officer

At a minimum the RSO will meet the following qualifications:

- A bachelor’s degree in the physical sciences, industrial hygiene or engineering from an accredited college or university, or an equivalent combination of training and relevant experience in radiological protection.

- At least five years of professional level experience in applied health physics, industrial hygiene, or similar work relevant to radiological hazards associated with site remediation. This experience should involve working with radiation detection and measuring equipment.

- A thorough knowledge of the proper application and use of health physics equipment used for the radionuclides present on-site, analytical procedures used for radiological sampling and monitoring, and the methodologies used to calculate personnel exposure to radionuclides present on site.

- Strong skills in written and oral communication and organizational management.

The RSO has the specific responsibility and authority to implement and manage the RPP during decommissioning including the overall content of the RPP during decommissioning. The RSO is also responsible for directing the radiological staff, as well as providing direction and guidance on the development, maintenance, oversight and implementation of radiation protection programs and procedures specific to the decommissioning project.

The RSO provides direction and guidance on, and is responsible for the development, maintenance, oversight and implementation of radiation protection programs and procedures specific to the site or project. As part of this responsibility, the RSO, or duly authorized representative, will review the radiation safety program annually and document the review.

8.5 Training

All personnel requiring access to the site including Licensee and CN employees, contractors, subcontractors, and visitors will receive radiation safety training/briefing based on the type of work the individual will be performing at the site. Radiation safety training/briefing requirements are tiered to provide an appropriate level of training to all personnel.

CN shall not assume that radiation safety training has been adequately covered by prior employment or academic training. The depth and breadth of the training program implemented will be commensurate with the radiological hazards that will be faced by the workers for the tasks being assigned. Training and job briefings will provide a fundamental knowledge and basic understanding of radioactivity, the relative hazards associated with radioactivity present at the site, PPE and methods to minimize radioactive exposure, as well as an awareness of those locations that are radiologically impacted at the site. Training will provide more specific information on the potential radiological hazards and the requisite radiological controls associated with the tasks being performed as part of decommissioning.

The Radiation Safety Training and briefings will be composed of two primary components, General Awareness Briefing and Rad Worker Training. General Awareness Briefing shall be required for workers who require unescorted access to the site, excluding any restricted areas. This training will include the principles and practices of radiation protection, the purpose and functions of protective clothing, monitoring devices that will be used (if applicable), general radiological safety among other topics and site specific information.

The General Awareness Briefing is accomplished in less than one hour. The second level of Rad Worker training will be for those individuals actively involved with the identification, removal and decontamination of radiological material at the site (i.e., Rad Worker Training). This minimum of four hours Rad Worker training is required for all workers and site personnel (Individuals) who in the course of employment are likely to receive an occupational dose greater than 100 mrem (1 mSv) in a year. Individuals who are expected to receive as much as 100 mrem of occupational radiation dose in a year are required, annually, to refresh their knowledge in radiation safety principles, procedures, and requirements.

All contractors are required to provide proof of training for job specific activities (i.e., health and safety training, the use of forklifts, manlifts, and construction equipment operator licenses). Contractor managers will be responsible for ensuring that their personnel receive training as described above, and commensurate with the work that will be performed.

Additionally, task-specific, and routine periodic briefings will be held for workers and other onsite personnel that will include such topics as decommissioning methods, safety issues, or site conditions. A daily safety meeting (tailgate) will be conducted during the POD briefing each morning between site management and onsite personnel and contractors prior to the start of work. Multiple daily meetings may be held that are specific to a particular task being performed.

Sign-in sheets will be required for daily POD briefings held on site. Each contractor may and is encouraged to provide added periodic briefings and tailgate meetings for their individual personnel on topics related to their specific decommissioning work activities. These components of the training program are considered vital to the safe, efficient, and compliant performance of the tasks performed during decommissioning activities.

Periodic briefings are designed to familiarize workers with the job-specific procedures and safety requirements associated with the scheduled work for the day or operational period, as applicable. These briefings will also allow for opportunities to discuss work improvement and lessons learned to provide for a safe work environment.

All personnel performing decommissioning activities will also be required to review and acknowledge CN’s site-specific HASP and the quality assurance program as appropriate. In addition, each contractor will be required to provide a copy of, and follow, their own HASP in advance of starting work. Personnel performing decommissioning activities will be briefed for the activities they will perform. Personnel performing activities under an RWP will be briefed on the requirements of the specific RWP being used.

All training/briefing will be documented by the person performing the training and provided to the site HSO or RPM as appropriate for maintenance of training records. This will include annual radiation training, routine periodic training, safety training, and daily briefings. Records of all training will be securely stored and maintained such that requisite worker training can be readily verified.

CN training records will include the names of training recipients, the individuals providing the training, the date(s) training was provided, the course name or type of training (e.g., Annual Radiation Worker Refresher training, tailgate safety briefing), and a brief description of the topic(s) covered. Task-specific RWP specific briefings will be documented on the RWP document. Training records are retained for at least two years, unless otherwise specified in the regulations.

8.6 Contractor Support

The Licensee has contracted site decommissioning and RSO support to CN. CN will maintain primary responsibility for implementation of site decommissioning including all aspects of radiation safety, monitoring and compliance with the DP, license and applicable regulatory requirements.

CN will subcontract the services of qualified professionals to support building demolition, shallow soil excavation with heavy equipment, deep excavation of soil with augurs, installation and abandonment of a monitoring well, asbestos abatement and compliance oversight, non- radiological air monitoring and waste transportation for recycling and disposal of non-rad and LLRW, as necessary.

CN personnel will report directly to the CN management who will in turn report to Licensee’s RSO and in turn to Licensee management. Subcontractors will report directly to CN management (both on and off- site). CN will maintain responsibility for all radiation safety and awareness training of CN staff and subcontractors.

Subcontractors will maintain responsibility for non-radiation training necessary to support the technical competency, health and safety of subcontractor staff in accordance with contractual requirements, applicable regulations and laws and industry standards of practice. A description of the specific training that will be provided to subcontractor personnel by the CN on behalf of the Licensee and the training that will be provided by the contractor is described in further detail in Section 8.5 (Training).

CN is committed to compliance with all radiation safety and license requirements applicable to site decommissioning work and elements of this DP.

9.0 Health & Safety Program During Decommissioning: Radiation Safety Controls & Monitoring for Workers

The following is a detailed description of the Heath & Safety Program during the decommissioning outlining the radiation safety controls and monitoring for workers, as documented in the Thermo Eberline LLC Final Decommissioning Plan.

9.1 Overview

The Radiation Health and Safety Program (RHASP) for implementation at the site during site decommissioning is designed to conform to the following two fundamental performance objectives:

- Compliance with the NMED RCB regulatory requirements (NMAC, 2009) as required by license conditions, thus assuring adequate protection of workers and the public from ionizing radiation during site decommissioning activities.

- Radiological safety measures (controls and monitoring) for workers will be commensurate with the risks associated with activities at the site as required by 10 C.F.R. 20.1101.

The information presented in this section includes a description of the radiation safety controls and types of monitoring that could potentially be used to ensure that internal and external exposures to workers are ALARA (including use of administrative controls).

While there is no expectation that actions to be undertaken under Phase 1 and Phase 2 will involve the management of materials contaminated with licensed radioactive materials, plans to address unexpected radiological conditions are outlined in this section. These plans will also apply to actions involving the removal and management of known contaminated materials under Phase 3.

The controls and monitoring will be implemented using written procedures including a process for managing procedure changes. Audits and inspections (including performance-based oversight) will be conducted periodically to assess the effectiveness of RHASP implementation. Deficiencies identified by audit or inspection will be documented and resolved promptly. A record generation and archival program will document RHASP implementation.

The current procedures or protocols used to conduct licensed activities will be augmented for site decommissioning through the amendment of the license to include this DP.

9.2 Air Sampling Program

During the scope of work performed under Phase 1 and Phase 2 demolition, processing and disposition there will be no potential to expose workers to airborne radioactivity to levels that would exceed those referenced in 10 C.F.R. 20.1502.b. None of the structures, foundations, concrete or asphalt surfaces remaining on site are contaminated and these features have been shown to meet NMED Surface and Volumetric Release Criteria for unrestricted release. In addition, none of the Licensee’s systems, equipment or building contents remaining on site are contaminated. Licensee equipment remaining on site has been determined to also meet NMED criteria for unrestricted release. Ground surfaces above the three areas of subsurface contamination that will be addressed as part of Phase 3 will be protected (cordoned off, posted, and covered with steel plates) to prevent inadvertent disturbance during the performance of Phase 1 and Phase 2 work.

As a precautionary measure, selected personnel within demolition work areas will be periodically monitored with lapel air samplers positioned within the individual’s breathing zone. An individual’s breathing zone is within one foot of the individual’s head. The use of lapels will be determined by the RPM during the various phases of demolition, waste segregation and waste packaging. The lapels will be calibrated on an annual basis. The lapels will be analyzed daily, primarily by the use of gamma spectroscopy. If supplemental alpha/beta analysis is performed, it will not be performed until the sample has been held for five days to account for the decay of naturally occurring radioactive material (NORM). Action levels for lapel samplers will be any positive detection of Licensee radioactive material above background.

Environmental air sampling will be performed during work activities in Phase 1. No positive detection of Licensee radioactivity in the air is anticipated. If positive detection of Licensee radioactivity is identified, stop work will be initiated. The potential cause(s) will be determined, and corrective actions will be identified and implemented prior to resumption of associated work activities. Further details on environmental air sampling are provided in Section 10.

During Phase 3 potentially contaminated soil will be removed from the former HRW area and areas G95 and G140 for residues of naturally occurring uranium ore. An enclosure may be constructed around each soil removal area as a radioactive contamination control barrier if warranted by site conditions. Alternatively, migration controls such as soil wetting may be sufficient and effective for the shallow, short-term types of excavation work required to address residues of naturally occurring uranium ore at G95 and G40. The need and type of radiation control will be stipulated in the RWP by the CN RPM. Air monitoring and sampling will be conducted as stipulated in the RWP by the CN RPM. Air sampling will be conducted outside the barrier as part of monitoring actions to ensure no spread of radioactive material to uncontrolled areas. Detailed requirements for air sampling during DP-3 will be contained in task-specific radiological control procedures and radiation work permits.

9.3 Respiratory Protection Program

The need for respiratory protection for radiological work is not envisioned at the site during Phase 1 and Phase 2 decommissioning work. None of the structures, concrete or asphalt surfaces remaining on site are contaminated and have been shown to meet NMED Surface and Volumetric Release Criteria for unrestricted release. In addition, none of the Licensee’s systems, equipment or building contents remaining on site are contaminated as it has been determined to meet NMED Surface and Volumetric Release Criteria.

Remaining impacted areas include subsurface soils at the location of the previous interior subsurface calibration wells and two isolated exterior areas that will be addressed during Phase 3 decommissioning work. During Phase 3 work activities, airborne samples will be collected to document potential airborne release of radioactivity during excavation and containerization of impacted soil.

For these areas, additional radiological controls will be implemented commensurately with the radiological hazard identified. Adequate radiological controls include performing surveys (e.g., external radiation exposure, radiological contamination and airborne radioactivity), radiation protection job coverage, contamination controls, and stop work criteria. These will be identified in appropriate RWPs for the tasks being performed. If, however, concentrations of airborne radioactivity are identified, the following steps will be used:

Stop work and evaluate process controls, engineering controls, or procedures to control concentrations of radioactive materials in air. This can be accomplished through the ‘Hierarchy of Controls’ where using this hierarchy can lower worker exposures and reduce risk of illness or injury.

- Elimination: Eliminate the exposure before it can occur.

- Engineering Controls: Requires a physical change to the workplace – Isolate personnel from the hazard.

- Administrative Controls: Change the duration of personnel work adjacent to the hazard to reduce the potential exposure.

- Personal Protective Equipment: Protect the worker with PPE (Respirators).

The purpose of the Respiratory Protection Program (REPP) is to establish the program requirements for respiratory protection against all industrial hazards in accordance with 29 C.F.R. 1910.134. If deemed necessary, respiratory protection would be administered in accordance with the current REPP. The REPP describes the selection of the appropriate PPE for the specific task and hazard, medical screening for the use of the respirator, fit testing, respirator qualification training, and the use, maintenance and storage of respiratory protection devices.

9.4 Contamination Control Program

During the scope of work performed in Phase 1 and Phase 2 there will be no anticipated generation, accumulation or spread of radioactive contamination. There will not be anticipated generation nor identification of “Contamination Areas.” None of the structures, concrete or asphalt surfaces on site are contaminated and have been shown to meet NMED Surface and Volumetric Release Criteria for unrestricted release. In addition, none of the Licensee’s systems, equipment or building contents remaining on site are contaminated. Licensee equipment remaining on site has been determined to also meet NMED Surface and Volumetric Release Criteria for unrestricted release.

As a precautionary measure, equipment, personnel, and the demolition areas will be periodically monitored for contamination. This monitoring will be performed with various monitoring instruments to identify fixed and/or removable contamination. Equipment and personnel will be monitored prior to exiting the demolition areas. Personnel will perform monitoring typically by hand and foot frisking with alpha, beta and/or gamma sensitive instrumentation. Equipment will be monitored through a combination of direct frisking and indirect frisking and analyzed on alpha, beta and/or gamma sensitive instrumentation. Equipment hauling waste material from the site will also be scanned with gamma sensitive dose rate instrumentation. The demolition areas will be periodically monitored for contamination via direct walk over scans with gamma sensitive instrumentation. Baseline measurements will be performed of the demolition areas prior to the start of active demolition. Incoming baseline surveys of equipment used within the demolition areas will be performed as dictated by RP Management. Action levels for monitoring of personnel and equipment will be any positive detection of Licensee radioactive material above background.

While the generation, accumulation or spread of contamination is not anticipated, controls will be in place to minimize this potential primarily through dust and sediment control during demolition. Dust suppression during the demolition of structure(s) and removal of impacted soils will primarily be through the use of wetting with water and by misting.

Stop work criteria will be delineated within project work plans to facilitate the suspension of work during periods of high winds when dust suppression is deemed no longer effective. Wind erosion controls will be implemented for the general demolition area requiring the use of water, or other dust palliative to be applied to soil surfaces and/or portions of the structure(s).

This is required to temporarily stabilize loose material and prevent dust generation. Sediment controls will be implemented to minimize and/or prevent the migration/transport of sediment outside of the demolition area. Examples of sediment controls that could be utilized are silt fences around the perimeter of the demolition area, protection/filtration of storm drain inlets, limiting entrances and exits to the demolition area, and ensuring effective controls at all entrances and exits are implemented to prevent off-site tracking of sediment.

Impacted soil areas will be cordoned off to restrict access and posted as RAM controlled areas. Contaminant reduction and exclusion zones will be established prior to the start of removal work to control the inadvertent spread of contamination during the removal. Impacted areas may be covered with polyethylene plastic and secured with tarps or coated with fixatives to prevent air and waterborne release from the impacted area during non-work periods. Containment with HEPA filtration will be employed to prevent fugitive dust emission during removal of Cs-137 impacted soils. Controls will be maintained within and/or surrounding each work area until authorized by the RSO.

Task-specific radiological control procedures and RWPs will specify contamination control and monitoring requirements for the excavation of the previous interior subsurface calibration wells and two isolated exterior areas to be completed under Phase 3.

9.5 Instrumentation Program

A broad array of instruments will be employed to support the health and safety program. Handheld instruments will include but are not limited to ZnS(Ag) and plastic scintillation detectors for alpha and beta measurements, NaI(Tl) detectors for gamma measurements, and Geiger- Mueller (GM), NaI(Tl), and/or ion chamber detectors for dose rate measurements. Particulate air samplers will be used to collect samples for airborne radioactivity analyses. An ISOCS is available for gamma spectroscopic analysis as necessary.

When not in use, field instrumentation is provided with protection from the environment and stored locally in temperature-controlled facilities protected from the elements.

Calibration and repair of instruments is performed by a licensed third-party provider or the instrument manufacturer, with the exceptions of instrument optimizations and mylar window replacements. Calibration is performed at least annually, or at other intervals as determined by the manufacturer. Instrument response and source checks are performed daily prior to use in accordance with established procedures.

Methodology for estimating uncertainty bounds varies between instruments. Uncertainty for gamma spectroscopic measurements is determined by manufacturer software in a commonly accepted form. Uncertainty for field scanning measurements are accounted for in calculation in scan speeds using standard methods described in MARSSIM. Uncertainty in fixed measurements is based on Gaussian statistics. The Gaussian distribution model will be used for analysis of uncertainty, unless low count rates collected per scan time are too low for the Gaussian distribution. In such cases Binomial or Poisson distribution models will be considered.

The calibration of air samplers is verified on site utilizing a TSI, Inc. Model 4040 flow meter calibrated at least annually by the manufacturer. This unit measures the flow rate of the sampler, which is checked against the sampler’s quoted flow rate, and corrections to calibration are made accordingly. The calibrator also enables consideration of temperature and air pressure influences. Calibration is performed annually or at a shorter interval if specified by the manufacturer.

9.6 Health Physics Audits, Inspections, & Recordkeeping

The annual review of the radiation protection program is conducted in accordance with the CN Audit Program. This review consists of a systematic review of the various elements of the program needed to comply with regulatory requirements. These elements include a review of the past audit history, the organization and scope of the program, training and instructions to workers, facilities, inventory and leak tests of sources, radiological survey instruments and calibration, radiological survey documentation and frequencies, receipt, transfer, and transport of radioactive material, personnel radiation protection to include external and internal dosimetry monitoring and measures to ensure exposures are kept ALARA, radioactive effluents and waste management, notifications and reports, posting and labeling, and recordkeeping. The RSO reviews audit findings and assigns actions to staff personnel to address all findings. Any findings of regulatory requirements are addressed in accordance with regulatory requirements. RPP audit records are maintained in accordance with the CN Records Retention Program.

10.0 Environmental Monitoring & Control Program

The following is a detailed description of the environmental monitoring and control program as documented in the Thermo Eberline LLC Final Decommissioning Plan.

10.1 Environmental Monitoring Program

This section provides an overview of the project environmental monitoring program to be implemented during site decommissioning. Environmental monitoring will occur through the collection and analysis of air samples and through in-situ monitoring of building material surfaces and soil within the demolition area. Baseline air measurements will be established prior to commencement of Phase 1.

10.1.1 Environmental Air Monitoring During Demolition

Particulate air samplers will be utilized to monitor the perimeter of the demolition and excavation areas in accordance with task-specific radiological control procedures and RWPs. These air samples shall be analyzed daily at the end of each workday, or as determined by the RPM. At a minimum, there shall be one sampler present on each of the North, South, East and West sides of the demolition area. Additional air samplers may be utilized interior to the demolition area and/or at the perimeter of the demolition area at various times during active demolition.

Due to the anticipated presence of NORM in these air samples, alpha and/or beta radionuclide analysis results may be erroneously high, and primary analyses for gamma emitting radionuclides should be performed to confirm the presence of Licensee radionuclides. No positive detection of airborne licensed radioactive material is anticipated. If such a condition is identified, workers will stop all work, determine the cause and corrective actions will be identified, approved and implemented prior to resuming associated work activities. Wind speed and direction will be monitored using an anemometer and recorded daily when obtaining the samples and logged appropriately on the air sample paperwork.

10.1.2 In-Situ Monitoring of Surface Soils and Pavement

Ground surfaces will be periodically scanned during the work week with gamma sensitive instrumentation. Project specific guidance will be utilized to provide guidance on how to conduct the survey as well as determine appropriate lower levels of detection and scan criteria. No contamination is anticipated, but if identified, all work will be stopped in the associated area, the extent of contamination will be determined and remediated, the cause of the contamination will be determined, and corrective actions will be implemented prior to the resumption of associated work activities.

10.1.3 Direct Radiation Exposure

While no external radiation dose hazards are anticipated to be present during Phase 1 and Phase 2, the environment will be monitored for direct radiation. Dosimeters will be placed at each of the property boundaries to the North, South, East and West. Periodic surveys will be conducted to establish dose rates at these locations. Direct radiation hazards will be monitored during Phase 3 with commensurate controls and monitoring in accordance with task-specific radiological control procedures and RWPs.

10.1.4 Environmental Sampling Quality Assurance

Environmental surveys and samples will be collected and analyzed in accordance with project procedures and the requirements of quality assurance sample collection, chain of custody, handling, storage and instrument maintenance and control including sample analysis requirements.

10.2 Effluent Control Program

During the scope of work performed in Phase 1 and Phase 2 there will be no anticipated generation, accumulation, or release of Licensee radioactive material to the environment.

Radiological effluent controls will be in place to minimize this potential primarily through the implementation of a SWPPP. The primary effluent control measures are expected to be dust suppression and erosion control. Best management practices will be delineated in the SWPPP and implemented and maintained during decommissioning.

Dust suppression during the demolition of structure(s) will primarily be using water. Stop work criteria will be delineated within the work package during periods of high winds when dust suppression is deemed no longer effective. Wind erosion controls will be implemented for the general demolition area requiring the use of water, or other dust palliative to be applied to soil surfaces and/or portions of the structure(s). This is required to temporarily stabilize loose material and prevent dust generation.

Sediment controls will be implemented to minimize and/or prevent the migration/transport of sediment outside of the demolition area. Examples of sediment controls that could be utilized are silt fences around the perimeter of the demolition area, protection/filtration of storm drain inlets, limiting entrances and exits to the demolition area, and ensuring effective controls at all entrances and exits are implemented to prevent off-site tracking of sediment.

As no radioactive effluents are planned during Phase 1 and Phase 2, the estimated offsite dose to members of the public from decommissioning activities is zero.

During Phase 3 containment will be used to control radioactive material removed from the excavation of Cs-137 impacted soil remaining adjacent to the former HRW. Contamination monitoring of the inside and the outside of the containment will be conducted in accordance with the task-specific radiological control procedures and RWPs.

Site boundary dosimeters will remain in place during decommissioning activities to assess the dose to members of the public.